Transportation & Logistics

Transportation & Logistics

Today's supply chains demand end to end visibility and real time tracking. Datalogic sensors and vision systems track parcels and shipments as they move through the warehouse and onto the carrier. Datalogic mobile computers, fixed image readers, and handheld scanners ensure visibility at shipping, receiving, through last mile activities such as delivery confirmation and signature capture. Dimensioning solutions also support exact cargo and baggage loading.

Applications

Airports

DATALOGIC SOLUTIONS FOR AIRPORTS

End-to-end traceability is one of the biggest challenge that airlines, airports and airground handlers are facing; offering a better service to their customers and increasing the passenger satisfaction.

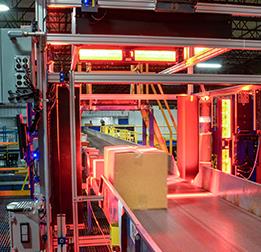

The number of mishandled bags has been reduced year over year, but the related costs are still significant for airlines and airports. The new IATA 753 regulation requires airline members to track baggage from the bag check-in to the passenger pickup. This means airlines and airports need to upgrade their BHS systems by adding more tracking points along every step of the bag’s journey.

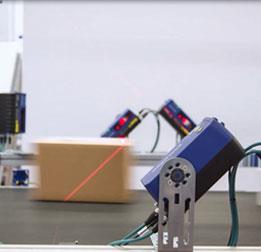

Datalogic can help airlines and airports to cover the gaps in bag traceability by offering complete solutions meeting the new IATA standard. In addition to handheld readers for bag check-in and mobile computers for the bag reconcilization process, Datalogic offers baggage tracking solutions on automated belts using stationary industrial barcode reading technology. Not only are these solutions easy to implement, they are highly customizable to fit all material handling requirements.

PIONEERING BAGGAGE HANDLING SYSTEMS

Datalogic has been one of IATA’s members, that defined the Standard Label used today in Airports (IATA Resolution 740) and has been chosen to define the Achievable Read Rate of a barcode reading system in real conditions (IATA report dated 23rd January1995).

Datalogic has always been a Baggage Handling System (BHS) pioneer: the company installed the first Automatic Reading Station for baggage handling in Europe (Milan - Linate, 1984). Since then, over 870 Datalogic reading systems have been installed in more than 200 airports across 5 continents (including Tokyo, Dubai, Hong Kong, Sidney, Paris, London, Kuala Lumpur, Chicago, and Atlanta), guaranteeing a fast, reliable and efficient service. Every day we work with our partners to minimize baggage loss, reduce delivery times, improve accuracy, and increase passenger satisfaction.

Datalogic remains a leader in the airport solutions market, offering breakthrough technologies from laser readers to vision systems.

Courier & Parcel

Today's transportation and logistics supply chains demand end-to-end visibility and real-time tracking of every single part or component. As well as ensuring everything is accounted for and in its correct location, it also provides a full audit trail and traceability of critical components and/or potentially dangerous, often required for meeting regulatory guidelines.

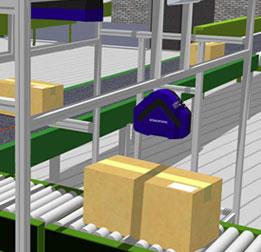

Datalogic’s range of sensors and vision systems help to track courier parcels and shipments as they move through the warehouse and onto the outbound carrier. Mobile computers, fixed 2D imager readers, fixed retail scanners and handheld scanners ensure visibility throughout shipping, receiving, and during last-mile activities such as delivery confirmation and signature capture (POD – Proof of Delivery).

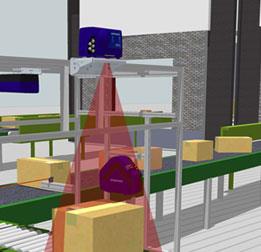

Dimensioning solutions also support cargo loading limits, exact dimensioning on high-speed sorters, and provide confirmation measurements, i.e., Legal for Trade. Below are some specific applications within this area that provide further details of the Datalogic products and how they bring real-world benefits to each use case in transport and logistics of courier parcels.

Postal

Postal services worldwide rely on Datalogic technology to ensure smooth and efficient movement of mail. Datalogic sensors and vision systems detect, size, weigh, and sort parcels at sorting facilities. Datalogic handheld scanners and mobile computers are used in postal offices for retail transactions, drivers license parsing, and to facilitate delivery with confirmation and signature capture.

Logistics

Dedicated Logistics and Third Party Logistics (3PL) organizations keep commerce in motion moving materials to factories, stock to distribution centers and items to retailers. To keep this flow of efficiency, logistics organizations rely on Datalogic products and technology. Vision systems, smart cameras, sensors and fixed barcode readers track items as they travel on high speed conveyors while industrial handheld scanners and rugged mobile computers put automation in the hands of workers as they ship, receive, pick, pack, and palletize.

Barcode solutions for e-commerce

DISCOVERING E-COMMERCE

The Covid-19 pandemic has had a massive impact on how we do business, including our purchasing methods. Online shopping and e-commerce businesses has gone through the roof. A decade ago, we felt the effects of the so called “Amazon effect”. However, we have now exceeded all predictions about e-commerce diffusion. A traditional logistic center is a fantastically complex structure, designed to accept items in an inbound area, splitting and recombining them according to order fulfillment requirements, and finally preparing the outbound product stream for shipment. What we can call "e-journey" begins with inbound logistics, continues with order fulfillment, sorting, outbound logistics, and ends with the outdoor logistics phase through to the last mile delivery.

SUPPLY CHAIN MANAGEMENT

Rising E-Commerce is having an increasing impact on retailers, including those businesses with established “brick & mortar” networks of stores. Supply chain management complexity has become greater and greater, and the concept of “omnichannel” is now a “must have” component of companies’ logistic strategies. Most of the well-known retail brands that already have established physical stores networks will move up to 50% of their business to online sales over the next 5 years. We can say without any doubt that barcode solutions for e-commerce underpin the management systems of all supply chain steps.

BARCODING IN E-COMMERCE

Barcoding in e-commerce is critical to the effective management of the entire process along the supply chain. Sorting and shipping systems have been using barcodes for a long time, but their adoption has increased in recent years as customers have found that they can dramatically reduce errors, increasing goods’ traceability. This means that barcode solutions for e-commerce are particularly cost-effective. Many customers use barcode scanning in areas such as receiving, put-away, replenishment, picking and packing, shipping, returns, cycle counts, and labor tracking.

BARCODE LABELING FOR E-COMMERCE

Barcode labeling in e-commerce is key for inventory management. Barcode technology provides all the data necessary for the attribution of goods to the correct recipients. Barcodes labels allow tracking of "what," "who," and "when" for all activities. A barcode can identify the order and access information such as products in the parcel, customer's name, delivery address, mode of shipping etc. So, barcode solutions for eCommerce use labels to convey all this information needed to complete the entire process correctly. With barcode scanners, data entry is fully automated, which avoids human error and allows workers to focus on more value-added activities.

DATALOGIC PRODUCTS FOR E-COMMERCE

Datalogic has a very wide range of products that can help your eCommerce business. We can divide them into three major categories: stationary industrial scanners, mobile computers, and handheld scanners.

Stationary Industrial Scanners

- Innovative platform and sensor with outstanding Field of View (FoV) and Depth of Field (DoF)

- Smart configurable lighting solutions with more color options in three power versions

- Configurable 360-degree multicolor visual feedback

- Liquid lens remote focus control for extreme flexibility in production

- High performance 9MP camera with integrated image processing system

- Image saving to external locations through the dedicated high-speed Gigabit Ethernet port

- White and red lighting options

- High performing, SW adjustable, dynamic focus.

Mobile Computers

- Ergonomic, very light weight and pocketable size to read 1D and 2D codes in any direction, and on any surface, including mobile screens

- Easy-swappable battery for a quick replacement

- Enhance productivity all over the store, running simultaneous applications smoothly

- Largest 4.3” high visibility display in its class

- Scan engine: 1D Imager, 2D Imager Standard Range, Mid-Range and near/far Extra Long-Range imager

- Handheld and pistol-grip form with 3 keyboard layouts

- Fully rugged 1.8 m drop and IP65 rating

- Choice between wireless charging or wired versions with dedicated docks

Handheld Scanners

- Ultra-rugged design, IP65 and IP67

- Embedded industrial connectivity, modular

- Wireless charging reducing TCO

- Doubled radio range and OLED display

- Smart batteries and diagnostics

- Minimal footprint, only 44 grams in weight, multiple mounting options (hand, neck/belt/pocket)

- 1D/2D reading capabilities up to 1.5 m / 4.9 ft

- Mobile app for pairing and settings

Success Stories

Video Gallery

Datalogic Smart Docking Station | One Device, Complete Versatility

Powerscan 9600 RFID Series | See Beyond the Visible

Memor 30-35 Family for Warehouse Applications