Outbound Logistics Solutions

Outbound Logistics Solutions

WHAT IS OUTBOUND LOGISTICS?

Simply put, it is the segment of the total supply chain that focuses on goods that are in the shipping area or a distribution center, waiting for the shipment. To achieve success in this leg of the supply chain, attention must be applied to key points in the outbound logistic processes specific to the warehouse location. It is essential to employ the most efficient and accurate methods in the different outbound stages such as pallet preparation, truck loading, and than shipment until the last mile delivery of the goods. To ensure a combined high degree of throughput and accuracy, it is paramount to determine the best outbound logistics solutions such as combining various automated technologies and up to the minute warehouse management and logistics management systems.

OUTBOUND LOGISTIC PROCESSES

While inbound and outbound logistics departments may be housed in the same warehouse, their processes and relationships differ. Inbound logistics focuses on procuring inbound supplies, storage, relationships with suppliers and reverse logistics (inbound return of goods), outbound logistic operations are concerned with arriving in the shipping area, final verification, loading onto vehicle etc. The shipment’s final destination may be to a distribution center, a channel partner’s warehouse, end user, or directly shipping products to customers. It is important to maintain good relations with all supply chain partners to help ensure accurate and timely delivery of goods.

The correct outbound logistic solution will vary by the type of finished goods being handled, the size of the warehouse, delivery methods employed, and the recipient of the goods. It is imperative to develop and maintain a clear-cut supply chain management strategy for successful outbound logistics processes. The ultimate goals of any strategies employed must be complete customer satisfaction, by ensuring the correct product is delivered in good condition and on time to offer an excellent customer service. The recent pandemic brought on unexpected sharp increase if e-commerce purchases which in turn impacted the supply and demand of finished products and deliveries within the whole supply chain. Customer expectations have increased with their ability to observe real time order and delivery statuses, leaving little room for errors in the delivery of their goods. Manufacturers may have the best designed product for their industry, but without a strong customer satisfaction base they will struggle to maintain success. It is therefore essential to identify what supply chain management strategy will fit best for the specific manufacturer that will ensure maintaining control of logistic costs, while developing and increasing their customer base.

DATALOGIC’S OUTBOUND LOGISTICS SOLUTIONS

As a global leader in the automatic data capture and automation industries, Datalogic is in a unique position to help outbound logistic processes seamlessly moving whether the operations are for one logistic line or 100 lines, or for one loading dock or 100 loading docks. Coupling Warehouse Management Software (WMS) and Logistics Management Software (LMS), solutions with a variety of Datalogic technological equipment in the execution of outbound logistics solutions will result in increased efficiency, accuracy, revenues, and customer satisfaction, and help to meet and exceed customer expectations. Datalogic can help logistics services achieve an optimum result of lowering logistics costs while increasing customer satisfaction.

PALLET PREPARATION

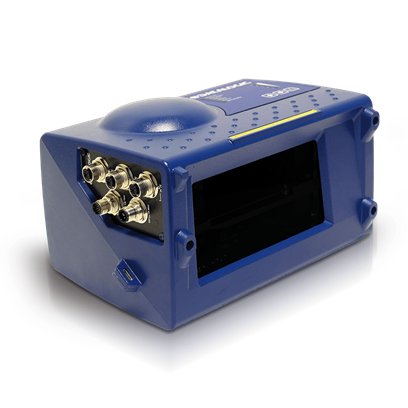

Pallet preparation is the final activity prior to shipment and offers the last opportunity to identify and remedy any errors before the product leaves the the “4 walls” of the Logistic Center. The Matrix 320 stationary industrial imager, with its wide field of view ,that offers a great tolerance in the label positioning, is the perfect device for pallet traceability. The 360° light feedback gives an immediate indication on the reading result, and is visible from long distance and even in very bright ambient conditions.

Pallet preparation is the final activity prior to shipment and offers the last opportunity to identify and remedy any errors before the product leaves the the “4 walls” of the Logistic Center. The Matrix 320 stationary industrial imager, with its wide field of view ,that offers a great tolerance in the label positioning, is the perfect device for pallet traceability. The 360° light feedback gives an immediate indication on the reading result, and is visible from long distance and even in very bright ambient conditions.

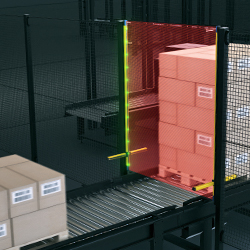

PALLETIZING - MACHINERY SAFEGUARDING

The extreme flexibility of the SH4 allows the safe passage of material by adapting to its size, direction and speed. For increased safety, the part of the light curtain to be muted can be limited to a fixed area or automatically adjust to the height of the material.

The extreme flexibility of the SH4 allows the safe passage of material by adapting to its size, direction and speed. For increased safety, the part of the light curtain to be muted can be limited to a fixed area or automatically adjust to the height of the material.

MATRIX 320 STATIONARY INDUSTRIAL SCANNER (SIS)

The Matrix 320 scanners are 2D image based stationary industrial scanners providing a superior Field of View (FOV). The Matrix 320 series brings liquid lens and C-mount solutions to the shop floor and an exemplary reading performance sure to keep the outbound logistics processes moving at top speed. To boost productivity in Intralogistics and Logistics segments, hands-free operations enjoy higher performance with the Matrix 320 5MP reader’s snappy reactivity, because of its outstanding Depth of Field (DOF), a new grid pattern aiming system, a new embedded distance sensor for the best user experience and reading throughput. Providing full industrial connectivity, 360° scan feedback, overall compactness, rotating connectors, fast replacing bracket, and the smart adapter that allows live focus this industrial SIS will be a welcome addition to outbound logistic processes such as outbound pallet preparation, order fulfilment, tote verification, and pallet traceability.

TRUCK LOADING

In the Outbound area, pallets need to be identified before leaving the Distribution Center (DC): a wide reading area coverage is needed, as numerous barcodes are typically distributed on one or more pallets. Thanks to its big 9 MP CMOS sensor and dynamic focus, AV900 perfectly matches these needs.

In the Outbound area, pallets need to be identified before leaving the Distribution Center (DC): a wide reading area coverage is needed, as numerous barcodes are typically distributed on one or more pallets. Thanks to its big 9 MP CMOS sensor and dynamic focus, AV900 perfectly matches these needs.

In the outbound area of a warehouse or distribution center, items are typically already stacked and wrapped on pallets, ready to be picked up by forklift trucks. Preparing a shipment involves identifying the products in each client’s order, picking these and placing them on the goods vehicle, and then updating the system with information on new stock levels before sending the shipment. Just like any other warehouse operation, the truck loading process needs to be automated and streamlined to meet the high throughput requirements to fulfil customer demand.

Precious few minutes saved during loading an individual truck soon add up, translating to huge savings by businesses on an annual basis. Pallets are typically quite large and reading multiple barcodes on a single pallet, or indeed on multiple pallets, requires a powerful barcode scanner that is able to identify items easily and quickly, even when barcodes are damaged, hard to read, or obscured by clear wrapping.

The AV900 from Datalogic, with its massive 9MP sensor and dynamic focus capability, will meet the toughest of demands. There are of course other ways of scanning outbound barcodes by using handheld scanners and PDT (Portale Data Terminal), but these don’t offer the same throughput as using a high-performance industrial imager such as the AV900.

AV900 STATIONARY INDUSTRIAL SCANNER

The AV900 high-performance industrial imager is a highly capable superior camera for transport and logistics applications. It sets a high bar for 2D image-based readers on all conveyor sizes, as well as static reading applications. In addition to its high-resolution capabilities, users can choose from different optics and set up either dynamic or software adjustable focus to tweak performance to suit specific needs. Its 9 MP CMOS sensor, dynamic or adjustable focus, and multiple lens options provide excellent solutions for unattended and attended object presentations in outbound logistic processes. The AV900 reader provides 60% additional coverage compared to other cameras widely used in logistics. It is capable of continuously capturing very high-resolution images up to 32 frames a second. Datalogic’s Pack Track™ Technology is instrumental in ensuring top performance at reduced gaps between items without risk of mis-assignments. The AV900 scanner will increase throughput and inspections throughout the outbound logistics processes such as order fulfillment and verification, carton and tote traceability, and reverse logistics. It will prove to be a valuable asset during pallet inspections to ensure the right items are being loaded for the order fulfillment.

SHIPMENT

When an item leaves the Distribution Center, destined for delivery to an end user, a restaurant or a shop, it's important to record this transition, as it's during this phase that the item property changes. The Memor 30-35, with its wide display, is the perfect solution.

When an item leaves the Distribution Center, destined for delivery to an end user, a restaurant or a shop, it's important to record this transition, as it's during this phase that the item property changes. The Memor 30-35, with its wide display, is the perfect solution.

Shipping is a critical part of any warehouse or distribution centre. Outgoing goods are shipped either to customers or to an onward storage facility. Scanning shipping barcodes is the final step in the warehouse management system. Successful scanning of outbound goods is imperative to capturing the relevant information and ensuring traceability.

Datalogic’s range of PDAs, such as the Memor 30-35, are designed to capture information easily thanks to having a large easy to read display. It’s important to be equipped with a device that is built to withstand harsh working environments and multiple drops to the ground. As operators may be required to go outside the 4 walls of the distribution centre it is important to maintain connectivity to the WMS, ensuring that the crucial stage when an item property changes to shipped is never missed.

MEMOR 30-35 PDA

- High performance 1D/2D scanning in a slim robust case with the ease of a swappable battery

- Complete with easy-to-use Android™ 9 which is upgradeable to Android™ 10

- Features Google Mobile Services (GMS) and is validated by Google to their ‘Android Enterprise Recommended’ program for rugged devices

- Runs on a superior octa-core platform

- Incorporates Datalogic’s industry first wireless charging system

- Embedded with wireless technologies for both indoor and outdoor activities

Products and Solutions

Video Gallery

Memor 30-35 Family for Warehouse Applications

Datalogic Matrix Family | Speed meets flexibility

Datalogic Memor 11 - Rugged Enough for Your Warehouse

Reasons to be Cheerful, from Datalogic | PowerScan™ 9600 Series