Secondary Packaging for Beverage&Food Solutions

Secondary Packaging for Beverage&Food Solutions

Beverage&Food secondary packaging designates the packaging used to group various pre-packaged products together. Secondary packaging does not come in direct contact with the actual product and as such, its use and application usually differs distinctly from those of primary packaging. Secondary packaging materials include cardboard cartons, cardboard boxes, cardboard or plastic crates, and shrink wrapping. However, it is important to be able to read, identify, and verify all forms of secondary packaging to maintain traceability of products in the supply chain.

Barcode and other identifying markers on secondary packaging must still be readable from a variety of different surfaces, even when damaged or subjected to wear and tear, and at any angle or lighting condition.

Print and apply barcode labels on secondary packaging require immediate checking and verification, usually at source, and require integrated camera technology. However, when products are bundled into secondary packaging in order to move larger number of items more efficiently, a new set of challenges arises when it comes to reading the secondary barcodes. Consider the case of barcode labelling applied to thermos shrink-wrapped packaging where the surface can be wrinkled, uneven, or curved, introducing new challenges in reading capabilities.

The risk of misreads can be very damaging to a business, especially when consumable materials that have a shorter shelf life are contained within the secondary packaging. With rising material costs, packaging materials can sometimes exceed the cost of the consumable materials contained within, the need to correctly verify products becomes more critical, especially when different labels exhibit slight variations such a language, nutrition labeling, or market-specific branding.

The requirements for the right scanning technology becomes a game-changer when used at scale in large secondary packaging operations that are used today.

PRINT AND APPLY BARCODED LABEL READING

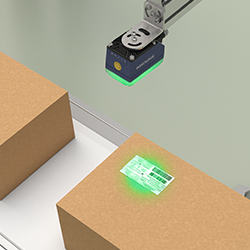

The Datalogic Matrix 120 is the smallest ultracompact industrial 2D imager on the market and is easily integrated into any space. The tiny form factor weighs less than 200g (7.1 oz), enabling installation directly on a label applicator arm.

This allows for an immediate double-check of a package's barcode label readability and positioning.

Real-time verification of accurate label application and barcode quality is made possible with the Datalogic Matrix 120, the smallest industrial 2D imager on the market. The ultra-compact unit integrates effortlessly into food and beverage packaging applications such as print-and-apply label verification and traceability.

The Matrix 120 is the perfect solution when small dimensions, lightweight, and performance are needed. Optional shorter output cables (only 100 mm in length) facilitate integration into OEM machines, such as on label applicator arms in print-and-apply systems. Food and beverage line packaging and distribution managers will appreciate how an on-board imager delivers an immediate double-check of proper label application, barcode readability, and accuracy of information content.

Options like a WVGA sensor for standard applications or a 1.2 MP sensor for high-resolution barcodes adapt the Matrix 120 for any use. A wide-angle version makes it the perfect solution for proximity reading. A 90-degree mounting capability and a polarized, glass-free reading window easily tackle barcodes on reflective label surfaces.

The Matrix 120 leads the market for customer ease of use because of DL.CODETM configuration software, an X-PressTM auto-configuration button, and an intuitive human-machine interface (HMI).

PRODUCT BUNDLES IDENTIFICATION

Single products are often packaged into bundles for marketing and retail logistics. Bundle-specific barcoded labels are applied to these packages. To maintain full product traceability, the Datalogic Matrix 320 stationary imager with up to 5 MP sensor resolution and multiple lighting options facilitates an effective bundle identification and tracking system.

The Matrix 320 is adaptable to even the most challenging reading conditions, like barcode labels applied to the uneven surfaces created by thermo-shrink plastic film. The unit also readily handles deformed barcodes, wide field-of-view (FOV) requirements, or reduced/variable environmental lighting conditions.

Product bundling is a popular method for manufacturers and retailers to increase sales, move inventory, and improve customer experiences. But any warehouse manager will tell you that this often leads to a logistics nightmare. The Datalogic Matrix 320™ stationary imager can help. Delivering the next evolution in intralogistics operations, the 2D imager brilliantly tackles traceability applications in food and beverage distribution and retail logistics.

Thermo-shrink wrap, often used on automatic packaging lines to bundle multiple SKUs, can create uneven or curved surfaces to which barcode labels are applied. Deformed or skewed barcodes are the result. The Matrix 320 stationary imager includes decoding algorithms that were task-built for these challenging applications, enabling effective bundle identification and full product traceability at all times. The stationary barcode scanner provides the highest reading performance in its class and easily handles reduced or variable lighting conditions and reflective label surfaces. An impressive field of view (FOV) enables the reading of multiple labels or codes and variable label positioning with a single reader.

The Matrix 320 2MP and 5MP models offer the ability to use high-quality C-Mount lenses from Datalogic or any C-Mount-compatible lenses from third-party vendors. These options provide the highest flexibility for solving the most demanding application challenges in the barcode scanner configuration.

CONSUMABLE MATERIAL VERIFICATION

The array of packaging consumables is nearly endless. Bags, pouches, shrink films, tubes, sleeves, wraps, roll stock, trays, cartons, and cases are each used in specific applications. Ensuring that the correct material is loaded onto a specific automated packaging machine at the right time is crucial. Processing the right material avoids faulty production and unnecessary waste.

Datalogic's PowerScan 9600 rugged handheld reader features unparalleled durability and reading performance on various material types and code and background color combinations. The unit will even handle codes printed with suboptimal print quality. With this type of flexibility, loading errors are eliminated, and downtime is minimized.

The costs of packaging consumables are rising. Bags, pouches, shrink films, tubes, sleeves, wraps, roll stock, trays, cartons, and cases are all more expensive today and can sometimes exceed the cost of the items they'll contain. Ensuring the proper consumable material is loaded onto an automated packaging line is essential to avoiding unnecessary waste and guaranteeing correct and flawless operations. Achieving that goal gets particularly tricky when the consumable packaging material is the same size and type for multiple products but with minor differences. Variations may be related to languages, nutrition labeling, or market-specific branding. These subtleties are nearly impossible for machine operators to recognize. As a result, mistakes can be made.

Avoiding operator mistakes and ensuring production traceability is essential in any packaging environment. The Datalogic PowerScan 9600 AR can help packaging facilities avoid unnecessary waste generation and related handling and disposal costs. The rugged handheld scanner has unparalleled durability and reading performance, excelling on most material types, and flawlessly handles variations in barcode and background color schemes. Even low-print quality barcodes are no match for the PowerScan 9600, which quickly reads the poorest imprints.

The PowerScan 9600 AR efficiently reads barcodes at multiple distances. This capability makes it practical to seamlessly scan pallets and cases in the warehouse and film reels in the consumable magazine. Additional features in the PowerScan 9600, like smart battery technology, wireless charging, Wi-Fi/Bluetooth connectivity, and IP65 and IP67 ratings, make it the easy choice for maximum flexibility, extreme reliability, and quality in a handheld scanner.

Products and Solutions

Video Gallery

Matrix 220 XAI | Ultimate DPM with the fastest auto-setup ever,...

Datalogic CODiScan | Mounting Options

Datalogic CODiScan | Charging Options

Datalogic CODiScan | Connectivity Options