Série Matrix 320

Plus de traçabilité pour une meilleure productivité avec des résolutions de 2 MP ou 5 MP

Découvrez et testez le dès maintenant

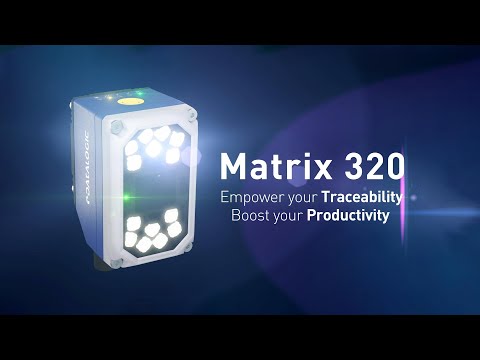

Empower Your Productivity

The most advanced imager ever

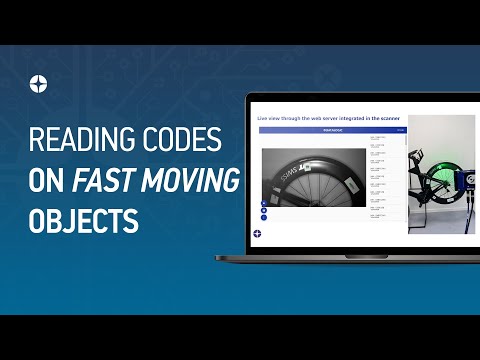

The incredibly versatile new Matrix 320 is an image-based barcode reader with an unrivalled field of view in its category that will transform your traceability capabilities in all logistics, intralogistics and shop-floor applications. It brings industry-leading performance, flexibility, and a low total cost of ownership to machine builders and end users, and effortlessly reads the most challenging of printed labels and directly marked parts. It has all the familiar features of the Matrix family such as easy setup with continual feedback, an extensive range of modular lens and lighting options, and cross network industrial connectivity for any situation. By utilizing the latest in sensor technology, the Matrix 320 provides the most cost-effective solution available on the market. In addition, it can be used in a fixed position, replacing the need for operators to manually scan items using traditional handheld barcode scanners. The Matrix 320 really does have everything you need.

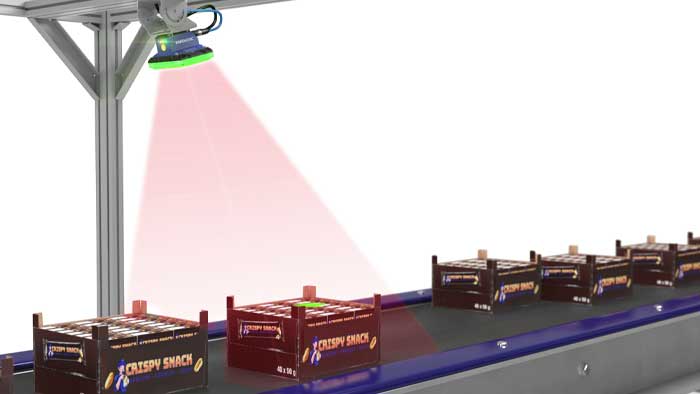

Empower Your Operations

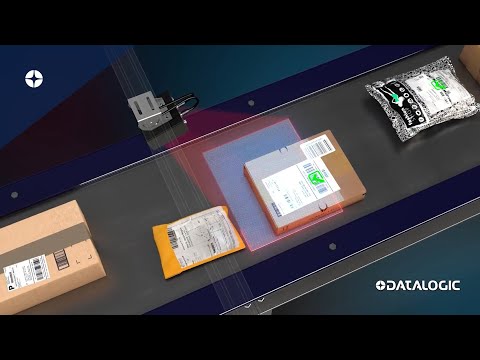

Outperform on challenging applications

The new Matrix 320 is equipped with a state-of-the-art 16:9 CMOS sensor that provides an unbelievable 3MP performance from a 2MP sensor. When combined with the advanced image processing electronics and smart lighting solutions, you have a 60 fps high-speed imager that can easily decipher the most challenging and hard to read barcodes such as those in intralogistics, or DPM barcodes such as those in the automotive and electronics industry. The combined large field of view and amazing depth of field also provides the capability to meet the highest speed demands present in the packaging industry. The Matrix 320 performs flawlessly, even with a combination of printed and DPM codes on the same surface. The Matrix 320 is built to bring top and maximum performance at the most competitive conditions.

Empower Your Applications

Fit all your needs with unlimited configurations

Customize the Matrix 320 to your exact needs, with an extended portfolio of lenses, lighting, filters and accessories. Being modular, you can easily adapt the imager to suit the vast majority of vertical applications. Lighting color and intensity are easily selectable based on the code type, material that the code is on, and the color of the material. If you prefer a simple plug and play solution however, you can purchase a ready assembled, fully functional model for use straight out of the box. The combination of these attributes give rise to easy stock management and overall reduced total cost of ownership for end users, partners, and machine builders alike.

Empower Your Installation

Everyone can install, configure, and operate

The Matrix 320, like the other Matrix readers, comes with a wide range of mounting brackets, rotating connectors and wiring options to cater to all types of installation. With plug and play setup for reduced installation time, the Matrix 320 has electronic focus adjustment when opting to use liquid lens (LQL) technology for extreme reading flexibility. It is simple to remotely change focus between batches in a live production environment without the need to open or touch the device. Remote focus on LQL lends itself well to when multiple images of the same object are required at different focal distances. The Matrix 320 also provides a 360º multi-color simple and easy visual status feedback, whether the camera is in configuration mode (blue), or whether or not a read has been successful (green) or not (red).

Empower Your Safety

Meet the demands for challenging times

The Matrix 320 has the unique benefit that it can be used by operators as a fixed reader in place of traditional handheld scanners in eCommerce and intralogistics applications. Growing demands for hygiene and safety in the workplace can be met as operators do not need to maintain scanner cleanliness and concentrate instead on other activities while utilizing a fixed Matrix 320 to read fast moving barcodes at high speeds. The simple aiming system with cross projection and highly visible read feedback on the label provides easy to see visual confirmation. As well as the increased hygiene and contamination control, the hands-free operation of the Matrix 320 leads to greater line efficiencies across a variety of industries and applications.

Téléchargements pour Série Matrix 320

Services

EASEOFCARE Programmes de Service

Notre mission est de fournir à nos clients un excellent service, à chaque interaction, adapté à leur profil et à leur secteur.

The central role of the customer also drove the creation of a new corporate division (the so-called “Customer Service”), which has centralised all the services provided by the Group globally, from order entry and confirmation to after-sales service and installation, by applying a performance indicator of client satisfaction such as the Net Promoter Score (NPS) used by many Fortune 500 Companies.

Le Service Client s'assurera d'avoir une réponse simple et cohérente à chaque demande. Nos spécialistes s'engageront auprès du client à mener chaque cas jusqu'à sa résolution complète.

L'organisation du Service Client de Datalogic propose différents services après-vente (accords EASEOFCARE). Elle est organisée pour garantir l'assistance professionnelle la plus appropriée en fonction du problème spécifique.

Le Service Client de Datalogic peut déployer sur le territoire une équipe de professionnels multilingues, avec une grande expertise technique sur l'ensemble de la gamme de produits.

Notre Services Standard Portfolio comprend :

Médias