Success Stories

Success Stories

Aerospace engineering pioneers implement laser marking technology for traceability - Datalogic

OVERVIEW

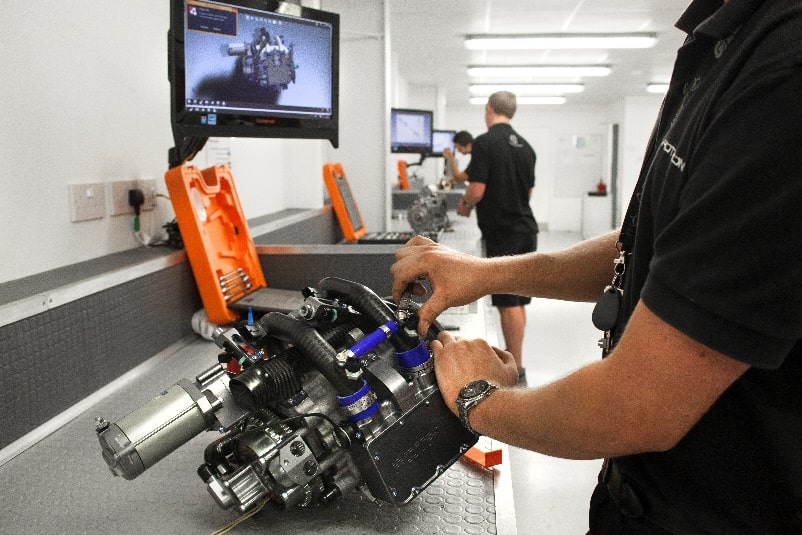

Gilo Industries Group encompasses an array of aerospace engineering companies developing breakthrough products and solutions which change the game across defence, commercial and recreational aviation applications. The desire to excel, to push the edge, has always been at the centre of their business; innovation and challenging convention are in the company’s DNA. By focusing its design, engineering and manufacturing expertise each company thrives on going beyond the bounds of what was previously thought possible and allows it to build the aviation technology of tomorrow. Working closely with specialists Laser Lines, Gilo Industries Group is achieving improved part marking throughput and accuracy with Datalogic’s Ulyxe laser marking system

THE CHALLENGE

“Across number of businesses within the Gilo Group, particularly Rotron Power that manufactures advanced rotary engines and Mako which produces cutting edge motorised surfboards, we anticipated a growing requirement to mark component parts with serial numbers and certification marks for improved traceability and audit purposes.” explains Tom Prince, Operations Manager at Rotron Power.

“Across number of businesses within the Gilo Group, particularly Rotron Power that manufactures advanced rotary engines and Mako which produces cutting edge motorised surfboards, we anticipated a growing requirement to mark component parts with serial numbers and certification marks for improved traceability and audit purposes.” explains Tom Prince, Operations Manager at Rotron Power.

Before deploying the Datalogic laser marking solution, serial numbers were added using a handheld engraver. “We found that by the sheer nature of the process, which relies heavily on the handwriting of the user, the handheld engraver produced very inconsistent results and often didn’t produce the professional standard we wanted to achieve for our brands,” continues Prince. “Although there was a desire to mark more individual, component parts, we really only marked whole engines as the process of engraving was too labour intensive. In addition, a lot of the individual parts that we wanted to engrave were quite small and the risk of damaging parts, which might contribute to a product failure was too high. We needed a solution that would provide clear part marking with 100% accuracy, that’s when we reached out to Laser Lines.”

THE SOLUTION

Gilo worked closely with specialist supplier Laser Lines, to find a suitable solution that would meet immediate and future requirements of its businesses that develop breakthrough products and solutions for defence, commercial and recreational applications.

Gilo worked closely with specialist supplier Laser Lines, to find a suitable solution that would meet immediate and future requirements of its businesses that develop breakthrough products and solutions for defence, commercial and recreational applications.

Gilo reviewed a number of different laser marking technologies, including CO2 and Fibre based laser systems, before selecting Datalogic’s DPSS (diode-pumped solid state) Ulyxe product.

“We discussed a number of laser technologies to Gilo at the company’s headquarters in Dorset,” adds Chris Ogden, Industrial & Scientific Laser Division Manager at Laser Lines. “After understanding more about the company’s unique requirements and ambitions for the technology, specifically the need to mark alphanumeric characters, logos and machine-readable codes on various sizes and types of materials including metal, metal alloys and plastic; it was our opinion that DPSS would be a better solution for Gilo as it delivers shorter bursts of energy which result in a much neater mark. An on-site demonstration of the Datalogic Ulyxe proved this to be the case, producing better, clearer marks on the full range of part materials, particularly on plastics.”

“We discussed a number of laser technologies to Gilo at the company’s headquarters in Dorset,” adds Chris Ogden, Industrial & Scientific Laser Division Manager at Laser Lines. “After understanding more about the company’s unique requirements and ambitions for the technology, specifically the need to mark alphanumeric characters, logos and machine-readable codes on various sizes and types of materials including metal, metal alloys and plastic; it was our opinion that DPSS would be a better solution for Gilo as it delivers shorter bursts of energy which result in a much neater mark. An on-site demonstration of the Datalogic Ulyxe proved this to be the case, producing better, clearer marks on the full range of part materials, particularly on plastics.”

In addition to the quality of the markings themselves, Gilo’s decision to install the Datalogic Ulyxe system was further influenced by its small form factor, minimal running costs and flexibility. “Compared with the other laser technologies we tested, the Datalogic system was really the best overall fit for our business,” states Prince. “The unit and workstation is nice and compact, so we haven’t had to re-configure the production floor to accommodate it and we have the flexibility to move the Datalogic laser into a new workstation housing if our future requirements change.”

THE RESULTS

After installation, Laser Lines provided training for a number of Gilo Industries’ staff, ensuring safe operation and accurate results at all times. “Laser Lines has been extremely supportive throughout the decision and installation process and were instrumental in the initial set up of the system to carry out a number of different marking tasks. Already, we can see enormous potential to save a huge amount of time as we increase the volumes of marking on engine components, not to mention the benefit of being able to enable future traceability of all our products. We are also excited about the ability to add professional looking logos and trademarks to products as we continue to grow our brand presence,” concludes Prince.

After installation, Laser Lines provided training for a number of Gilo Industries’ staff, ensuring safe operation and accurate results at all times. “Laser Lines has been extremely supportive throughout the decision and installation process and were instrumental in the initial set up of the system to carry out a number of different marking tasks. Already, we can see enormous potential to save a huge amount of time as we increase the volumes of marking on engine components, not to mention the benefit of being able to enable future traceability of all our products. We are also excited about the ability to add professional looking logos and trademarks to products as we continue to grow our brand presence,” concludes Prince.

Kamran Farooq, UK & Ireland Sales Manager, Manufacturing at Datalogic adds, “Accurate traceability of components and finished products is a vital element of modern-day manufacturing processes. We are delighted that Gilo Industries has found the Datalogic Ulyxe system offers the best fit and results for their unique requirements and hope that laser marking adds increased value to their operations, as they continue driving innovation within aerospace engineering.”