Inbound Handling Solutions

Inbound Handling Solutions

WHAT IS INBOUND HANDLING SOLUTIONS?

Diligent inbound logistics makes up a crucial requisite for a healthy flow of manufacturing and distribution operations, having a direct impact on production rates, supply chain management, and customer satisfaction. In this page, we will explore the currently available inbound handling solutions, helping you find the right match for your specific needs.

DEFINING INBOUND HANDLING

Logistics works as the circulatory system that synchronizes the streaming of goods from their point of origin up to the final consumers.

Here are a few examples of inbound handling activities:

- Material acquisition. At this stage, the company identifies providers for the goods it needs, then negotiates a price and proceeds to purchasing.

- Receiving. Once the goods arrive at the warehouse, the receiving staff unloads the materials, scans barcodes or RFID tags to count and identify them, then moves each item to its location.

- Cross-docking. It is an order processing technique that coordinates the parcel exchange between supplier and courier only, completely bypassing the procedures of picking.

Each activity has its own potential automated solution but finding the right one for concrete case scenarios can be confusing to say the least. It is time to dive more into the complex world of inbound handling solutions for courier and parcel operations.

WHAT ARE THE BEST INBOUND HANDLING SOLUTIONS FOR COURIER AND PARCEL?

The global industrial and commercial ecosystem has been transformed dramatically after the e-commerce revolution. Companies driving logistics operations like material handling or courier and parcel services need to adjust quickly to the new standard of efficiency set by automation technology if they want to keep thriving. Selecting the right inbound handling solution can speed up your adaptability and help you reduce costs. We picked the most important ones for your consideration.

BARCODES AND RFID

Barcodes are designed to simplify. To begin with, they reduce human error, by eliminating the need for manually entered data. Moreover, barcodes make item tracking precise and cheaper, reducing inventory costs. In addition, they can be applied to goods individually and uniquely, providing detailed information per tag or per lot.

RFID tags and readers are placed in strategic locations at the warehouse, to track inventory items without the use of man-operated scanners. The efficiency is increased by streamlining processes that would otherwise slow down the output rate.

PALLET ACCEPTANCE AND CHECK SOLUTIONS

Barcode scanners represent a helpful inbound handling solution for the warehouses to manage their inventory as they power up essential operations such as the locating and picking of required items. Moreover, when mobile computing is added to scanning devices, it gets easier to monitor each part of the inventory in real time.

Handheld devices use portability, optical range, and flexibility to cut time-waste to the bone with an agile, wireless data capture. Consider how huge an advantage it is when it comes to inventories with frequent physical transportation.

WAREHOUSE MANAGEMENT SYSTEMS

A Warehouse Management Systems (WMS) is a software that enables perfect visibility over the inventory, while managing order fulfillment operations from distribution centers to store shelves.

This solution makes optimization possible by coordinating efforts, space, and equipment investments with the available workforce, resources, and materials.

There is more. From product tracking to picking functions, from inventory control to shipment management and courier tracking, there are many reasons why a company should be equipped with a WMS, whether it is a traditional warehouse, an automated warehouse, or a 4.0 warehouse.

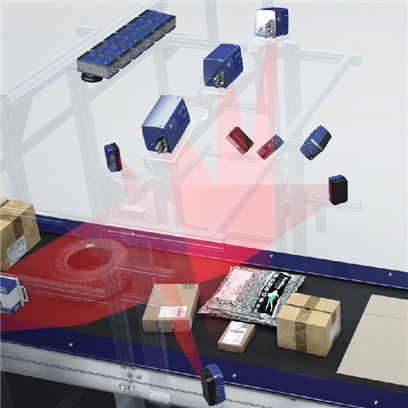

INBOUND HANDLING SCANNER SOLUTIONS FROM DATALOGIC

The following are Datalogic's main Inbound Handling Scanners:

- Rhino II – The vehicle mount terminal that delivers real-time, accurate details on pallets locations, and work instructions to forklift drivers.

- PowerScan XLR scanner – The handheld scanner for barcodes manual scanning that can endure over 10 million triggers.

- Matrix 320 – The stationary 2D imager reader for automated barcode scanning with modular lighting and filters options.

- DM3610 – The dimensioning unit for high performance, overhead dimensioning, and. weighing.

- AV900 – The industrial imager for the automated scanning of barcode and images leveraging its impressive 9MP sensor.

- Skorpio X5 – The key-based mobile computer for pallet acceptance and check, available as Linear Imager, Standard 2D Imager, Mid-Range Imager, and 2D near-far top performing Extra-Long Range (XLR).

Products and Solutions

Video Gallery

Handle more with Datalogic CODiScan™

Reasons to be Cheerful, from Datalogic | PowerScan™ 9600 Series

#DidYouKnow | Trigger testing

#DidYouKnow | Wireless Charging